Closures

We produce state of the art compression molded closures.

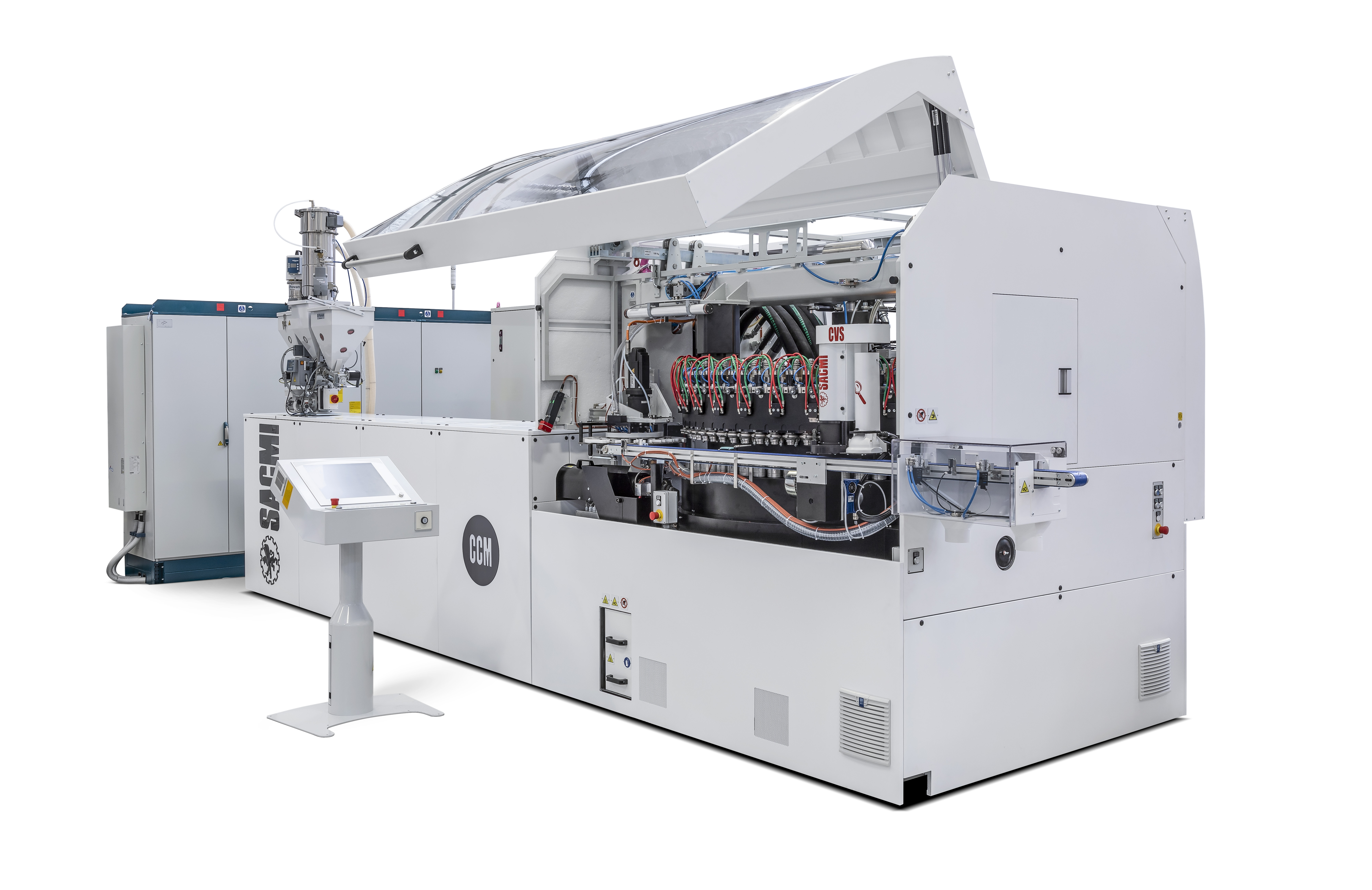

Western Container produces HDPE closures for the system. Our PCO1881 closure, made from High Density Polyethylene (HDPE) on a Sacmi compression molding machine. They can be manufactured in any color and printed with up to three colors using a state-of-the-art Rotoprint system. It features a folded and slit tamper-evident band for maximum product protection. The production line includes full vision inspection to ensure the highest quality.

Compression molding is a widely used process for manufacturing HDPE beverage closures due to its efficiency and precision. HDPE material is fed into a plasticizing unit, where it is heated to a specific temperature to become pliable. The softened HDPE is cut into small, uniform pellets, which are then fed into the molding machine.

The pellets are placed into open mold cavities, and the mold closes, applying pressure to shape the material into the desired closure. The molded closures are cooled within the mold to solidify their shape. Once cooled, the finished closures are ejected from the mold. Later in the process, the caps are printed, inspected, and placed into boxes or totes for shipping.

Our Equipment Supplier

- SACMI